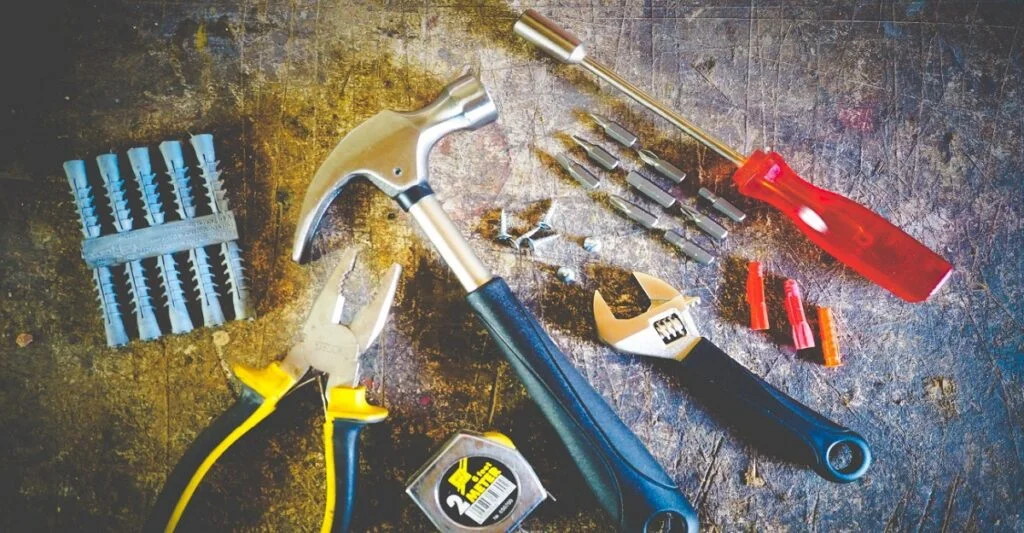

Maintaining hand tools is crucial for their longevity and performance. By keeping your tools in good condition, you can ensure that they remain easy to use, allowing you and your team to work faster and more efficiently. In this article, we will learn 10 ways how to maintain hand tools, the importance of maintaining tools, and more.

How To Maintain Hand Tools For Longevity And Performance?

Proper maintenance involves simple practices such as regular cleaning, storage in a dry environment, and routine inspections for wear and damage. Therefore, taking care of your hand tools not only prolongs their lifespan but also contributes to the success and safety of your work.

10 Ways Of Maintaining Tools And Equipment

Maintaining hand tools is essential to ensure their longevity and performance. Here are ten ways to maintain your tools and equipment:

Regular Cleaning

Clean tools after each use to prevent corrosion and damage. Use a microfiber cloth or a brush to remove dirt and debris.

Proper Storage

Store tools in a dry environment to prevent rust and damage. Use a toolbox or a storage container to keep them organized.

Inspect Tools Regularly

Check for wear, damage, or any other issues that may affect performance. Replace any damaged or worn-out parts.

Lubrication

Apply a light coat of lubricant to moving parts and hinges to prevent friction and wear. Use a lubricant that is appropriate for your specific tool.

Use The Right Tool for the Right Job

Using the wrong tool can damage both the tool and the workpiece. Choose the right tool for the job to ensure optimal performance.

Handle With Care

Avoid dropping or mishandling tools to prevent damage. Use a tool belt or a tool bag to keep them secure.

Protective Coating

Apply a protective coating to prevent rust and corrosion. Use a rust inhibitor or a protective spray.

Safety Precautions

Use tools with the appropriate personal protective equipment (PPE) to ensure safety. Wear gloves, safety glasses, and other protective gear as needed.

Proper Posture

Maintain proper body posture while using hand tools to prevent injuries. Use a workbench or a table to keep tools at a comfortable height.

Regular Maintenance

Perform routine maintenance tasks to keep tools in good working condition. Sharpen blades, replace batteries, and perform other maintenance tasks as needed.

By following these ten tips, you can ensure that your hand tools remain in good condition, allowing you to work more efficiently and safely.

Care And Maintenance Of Regular Used Hand Tools

Hand tools such as screwdrivers, wrenches, hammers, pliers, and other common household tools require proper care and maintenance to ensure their longevity and performance. Here are some specific care and maintenance practices for these tools:

- Screwdrivers: Keep the tips clean and sharp. Avoid using them as pry bars or chisels, as this can damage the tips. Store them in a dry place to prevent rust.

- Wrenches: Keep them clean and free of debris. Lubricate the moving parts to prevent rust and corrosion. Store them in a toolbox or a storage container to keep them organized.

- Hammers: Keep the head clean and free of rust. Replace the handle if it becomes loose or damaged. Store them in a dry place to prevent rust.

- Pliers: Keep the jaws clean and free of debris. Lubricate the pivot point to prevent rust and corrosion. Store them in a toolbox or a storage container to keep them organized.

In general, it is important to keep all hand tools clean and dry. After each use, wipe them down with a rag or old towel to remove dust, grease, and debris. Inspect them regularly for wear, damage, or any other issues that may affect performance.

Importance Of Maintaining Tools And Equipment

Maintaining hand tools and equipment is crucial for various reasons, including increased efficiency, cost savings, and improved safety. Here are the benefits of maintaining tools and equipment:

- Increased Efficiency: Well-maintained tools operate at peak performance, allowing you to work faster and more efficiently.

- Cost Savings: Regular maintenance can prevent expensive repairs and replacements, saving you money in the long run.

- Improved Safety: Maintaining tools and equipment reduces the risk of accidents and injuries, ensuring a safer work environment.

- Longer Lifespan: Proper maintenance extends the life of your tools and equipment, allowing you to use them for a longer period.

- Better Performance: Regular maintenance ensures that your tools and equipment perform optimally, reducing the need for frequent replacements.

- Reduced Downtime: Well-maintained tools and equipment are less likely to break down, reducing downtime and increasing productivity.

- Increased Value: Maintaining tools and equipment preserves their value, making them more attractive for resale or trade-in.

By maintaining your hand tools and equipment, you can enjoy these benefits, leading to a more efficient, cost-effective, and safer work environment.

How Can You Prevent Rust On Hand Tools?

To prevent rust on hand tools, follow these steps:

- Keep Storage Clean And Dry: Ensure that the place where you store your tools is dry and clean. Avoid storing tools in damp or humid environments, as this can lead to rust.

- Use A Rust Inhibitor: Apply a rust inhibitor, such as WD-40, to your tools after cleaning them. This can help prevent rust and corrosion.

- Let Tools Soak: Soak rusted tools in a rust removal solution, such as vinegar and salt, for an hour before wiping them down.

- Rinse Away Rust And Acid: After soaking the tools, rinse off the rust and acid, and dry them thoroughly.

- Apply A Protective Coating: Apply a protective coating, such as paste wax or a rust inhibitor, to each tool to prevent rust and corrosion.

- Keep Tools Dry: Avoid getting your tools wet, as moisture can lead to rust.

- Store Tools In A Dry Environment: Store your tools in a dry place, such as a toolbox or a storage container, to prevent rust and damage.

By following these steps, you can effectively prevent rust on your hand tools and keep them in good condition for a longer period.

The Final Words

Maintaining equipment is crucial for its longevity and productivity. Neglecting maintenance needs, using inadequate replacement parts, and failing to implement a maintenance routine can lead to increased costs and decreased productivity. Preventive maintenance is cost-effective as compared to corrective maintenance.

Adhering to the manufacturer’s maintenance plans, implementing a robust maintenance routine, and investing in genuine parts can protect your equipment investment and ensure its reliable performance for years to come.

Suggested Reads: How To Wear A Tool Belt Properly?

FAQs (Frequently Asked Questions)

What are some common mistakes to avoid when maintaining tools and equipment?

Some common mistakes to avoid include neglecting safety guidelines, not cleaning equipment properly, skipping regular inspections, and ignoring or delaying repairs.

How can you prevent rust on hand tools?

To prevent rust on hand tools, keep storage clean and dry, use a rust inhibitor, let tools soak, rinse away rust and acid, apply a protective coating, keep tools dry, store tools in a dry environment, regularly inspect tools, use the right tool for the right job, and handle with care.

What are some best practices for implementing a maintenance routine?

Best practices include reliable task prioritization, material availability, continuous improvement, CMMS utilization, performance monitoring, and process automation.

How do you clean and store hand tools?

Clean hand tools after each use before returning them to storage. Wipe them down with a rag or old towel and be sure they are free of dust, grease, and debris before you put them into their proper places. Store them in a dry place, preferably in a toolbox, and more.

Why is maintaining hand tools important?

Maintaining hand tools is important because it increases efficiency, saves costs, improves safety, extends the lifespan of tools, enhances performance, reduces downtime, increases value, and ensures compliance with safety and regulatory standards.

Adam is a tool geek who just loves making and breaking things. Doing the home improvements works and repairing things with his tools is his favorite past time. He loves to keep his tools arranged and sorted. On this blog, he shares his experience and knowledge.